Had There Been Computer-Aided Designs for F-1 Engines,...

- Shambhavi Nandan

- Mar 12, 2020

- 4 min read

Updated: Mar 15, 2020

On July 20, 2019, the world celebrated the 50th anniversary of the historic first moon landing ever attempted successfully by humankind. The first moon landing was part of the NASA’s Apollo 11 lunar mission, which carried three American astronauts to space namely Commander Neil Armstrong, Command Module Pilot Michael Collins and Lunar Module Pilot Buzz Aldrin. Out of them, only Neil Armstrong and Buzz Aldrin formed the crew that landed the Apollo’s Lunar Module Eagle on July 20, 1969, at 20:17 UTC. In all sense, the first human moon landing on July 20, 1969 was and will remain one of the most daunting achievements of modern science and engineering.

However, a few people will appreciate the fact that although the moon landing was remarkable, the mere lift off of gigantic Saturn V rocket from the Kennedy Space Center on the Merritt Island, Florida on July 16, was even more remarkable. And the reason was the stable performance of the massive F-1 engines propelling Saturn V rocket away from the Earth into the space. But all was not rosy for the mighty F-1 engines during the development and testing phase. At the time of performance testing for the maximum thrust, the F-1 engines were simply exploding within fraction of seconds. The reason for this was the occurrence of combustion instabilities within the F-1s.

In layman terms combustion instabilities resulted in the intense vibrations in the F-1 engines after the burning of the rocket grade Kerosene fuel in the presence of the liquid Oxygen, which was used as oxidizer. As a consequence of these violent vibrations the initial models exploded on the test platforms straightaway, almost derailing the American dream of going to the moon. To address this problem, team of engineers from Rocketdyne – the company responsible for the manufacturing of F-1 engines for NASA’s Apollo mission – worked day and night, and performed around thousands of tests on “real” F-1 engines. After spending billions of dollars, the outcome of these countless tests resulted in the ingenious design of putting baffle like structures in the fuel injector plate in the F-1 engines.

The final design of F-1s constituted 12 radial baffles and 2 circular baffles, and this layout worked so well for the engines that even the artificially introduced perturbations in the engines died out in fraction of seconds. However, this ingenious baffle design for the fuel injector plate in the F-1 was called a “trial and error” achievement by the senior rocket engineers, since, no one knew the actual reason that why the design worked with a layout of 12+2 baffles.

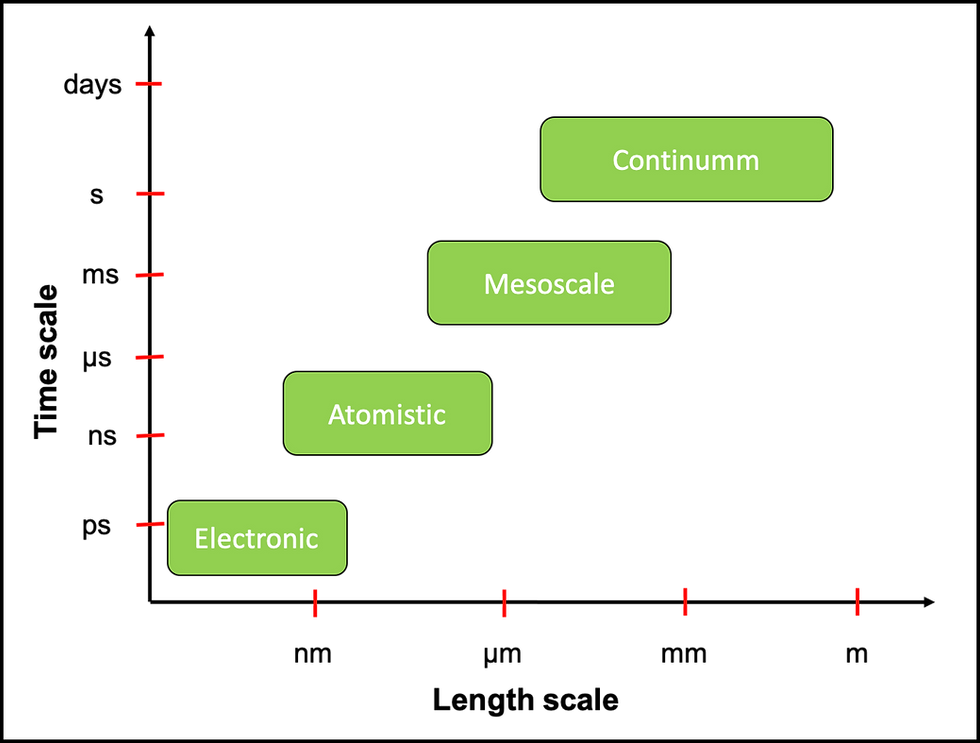

The new design surely worked but, was the design optimal? and was it the only design to overcome instabilities? Many such questions remained unanswered at that time due to the unavailability of a simpler approach to research on the F-1 engines without going for full scale tests. One such simpler approach would have been provided by the computational science based tools, but unfortunately, there were none 50 years ago. The use of computational science based approach would have been the preferred choice by rocket engineers, if they would have encountered the problem of combustion instabilities in F-1 engines in today's world. They would have gone for designing a computer model of F-1 engines and studied the combustion instability by the means of Computational Fluid Dynamics (CFD). This would not only had saved billions of dollars but also would have answered the unanswered questions pertaining to the baffle design.

However, the opportunity for research in the design optimization of F-1 engines is still not obsolete. There is a possibility that in the near future the giant interplanetary rockets will be powered by the updated versions of F-1 engines. And this possibility is not completely unfounded, since recently a group of young NASA engineers with a CAD expert company ShapeFidelity had tried to resurrect the mighty F-1s by using the modern CAD tools. In the photo displayed below ShapeFidelity is able to create a 3D CAD of F-1, accurate to the length-scale of the smallest bolt.

Computational sciences have completely transformed today's aerospace scenario. Presently in the rockets development industries, the computational models, both simple and CAD like, are used to carry out CFD studies for the design optimization of the massive rocket engines before their actual industrial fabrication. This computational approach allows the rocket engineers to test different designs with different layout of fuel injector plates, combustion chamber, nozzles etc. for their ability to reduce combustion instabilities within the engines. Once, the most optimal design is sorted out computationally, the same design is manufactured industrially, and full-scale tests are conducted. This not only leads to the overall cost reduction but also saves time, which otherwise would have been invested into trial and error experiments in a highly disproportionate way.

With the further advancements in the computing power of the world, the future of computational sciences in the aerospace industry is very bright and promising. However, having said that, no matter how much we have progressed today computationally, the story of taming the mighty F-1 engines by the hard working and perseverant engineers and scientists, by thousands of trials, will always remain one of the most remarkable engineering feats in the history of humankind.

Comments