Modelling and simulation in nuclear reactor systems

- Vasudha Verma

- Mar 24, 2020

- 4 min read

As the global energy demand continues to witness an upward trend, the need to match this increase in an environmentally sustainable manner is paramount. It is important to move toward low-carbon clean energy sources such as nuclear power, which is an excellent carbon-free economical energy solution. With a current world electricity production share of 10%, today, nuclear energy along with hydro-power provides three-quarters of the world's low carbon energy generation. Early nuclear reactor developments were based on a series of small experiments and a lot of analytical calculations. As the nature and scale of the nuclear system being designed became progressively complex, it was not possible anymore to continue to perform newer experiments for, say, design optimization that needed small parameters adjustment. Increasingly, computer simulations became a major tool for investigating such complex systems and introducing newer design concepts.

A nuclear fuel cycle involves a series of industrial processes that lead to generation of electricity using uranium as a basis. The sheer array of processes involved, beginning from nuclear fuel fabrication, fuel utilization, heat generation, energy production up till nuclear waste disposal, makes nuclear energy systems highly complex and tightly-coupled systems. One of the most crucial link in this chain is a nuclear reactor. In a nuclear reactor, thermal energy generated via nuclear fuel utilization is converted into electrical energy. Typically, this involves fission, which is a process of splitting uranium atoms wherein the heat released in the reaction is used to produce steam that aids in generating electricity via turbine generators. In the most common nuclear reactor type operating across the world today, known as the light water reactor (LWR), the reactor core contains nuclear fuel assemblies, where heat produced by the fuel is transferred to the surrounding water (fluid), and transported to the steam power cycles. The heat transport occurs directly in the form of steam in boiling water reactors (BWR), and sometimes, indirectly via heat-exchangers in pressurized water reactors (PWR), both of which are classified under LWRs. Here, water acts as both a coolant for cooling down fuel assemblies and as a moderator, for slowing down the neutrons produced during a nuclear fission reaction. Through these processes, neutron density, nuclear fuel temperature and water properties are closely interlinked, and therefore, nuclear reactor systems are multi-physics in nature. Another aspect adding to the complexity of the nuclear reactors is the heterogeneity of the nuclear components resulting in phenomena occurring at different spatial scales (few mm to meters). For instance, a typical PWR has core height ~4 m, radius ~3.5 m, and contains about 150 fuel assemblies of average height ~20 m. The fuel assemblies are further made up of ~300 fuel pins of diameter 1 cm each, as shown in the figure. As the fuel resides inside the fuel pins, there is a strong correlation between the fuel pins and the reactor core in whole, and as a result, the neutrons are spatially distributed across the core. The coolant properties and fuel temperature also varies radially and axially in the reactor. The interlinking of local and global processes due to the heterogeneous composition of the system contribute towards the multi-scale nature of the nuclear reactor systems.

As you can see, the complexity of a nuclear reactor system makes it difficult to judge what is happening inside the system. Therefore, the nuclear industry uses simulations based on computational models that represent such complex processes as closely as possible while greatly reducing the time necessary to predict and evaluate nuclear systems behavior, and perform an after-assessment of the occurred events. The simulation tools are based on models that allow for detailed calculations of neutron transport, heat transfer and fluid dynamics occurring in and/or between the different components of a nuclear reactor, i.e. fuel pin, rod, fuel assembly, reactor core, reactor vessel, reactor containment etc. The objective of the computational models is to predict the behavior of the physical variables over space and time during normal operating conditions as well as accidental conditions. The codes solve a given set of equations describing the above mentioned processes using appropriate numerical methods, closure relations, empirical models and input data that describes the reactor conditions. These computer simulations help in achieving optimized reactor performance. Not only are they useful for day-to-day operation of nuclear plants, the simulations also aid in design and licensing purposes, validation and independent regulation of the nuclear technologies.

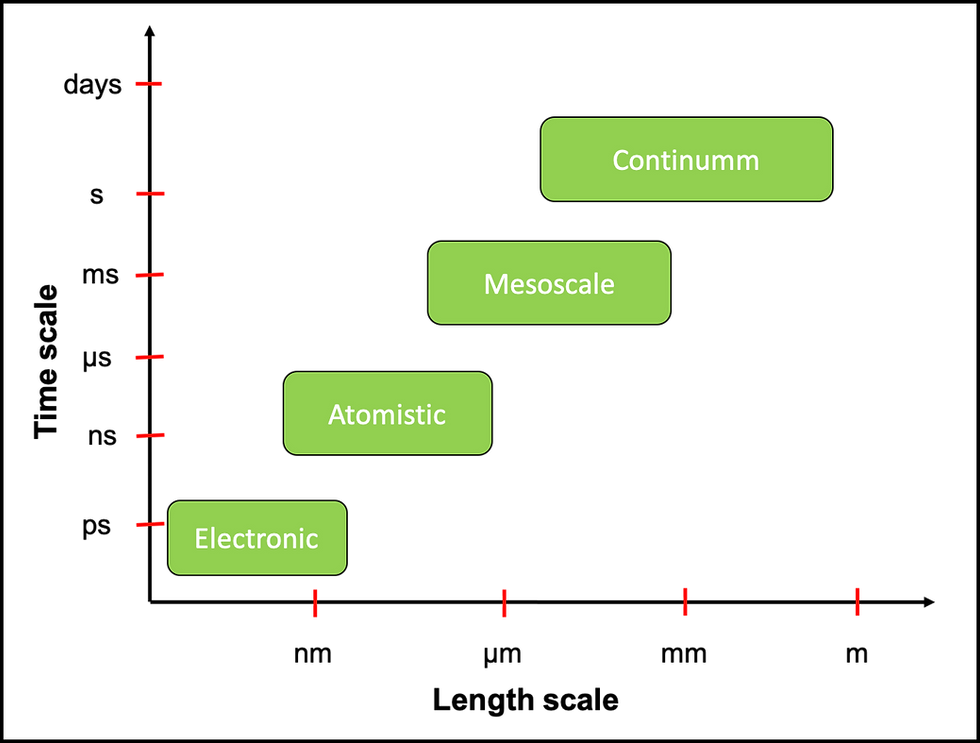

Traditional nuclear reactor codes, developed in the late 1970s - early 1980s, simulate a limited set of key physical phenomena with a lot of assumptions and large uncertainties, yet ensuring reliable and safe operation of the system. The performance of the codes is optimized in a way to achieve a trade-off between how closely the model represents the reality, i.e. the accuracy of the results and the time spent on performing the simulations, i.e. the computational cost. With the advancements in computing power, huge efforts have been made in the last decade to achieve more accurate models that take into account the true multi-physics and multi-scale nature of the nuclear systems as accurately as possible. The advanced modelling and simulation techniques enable us to gain insight into the nuclear reactor world in ways not possible with traditional methods alone. Such developments also contribute towards the design and operation of future nuclear energy systems.

Comments